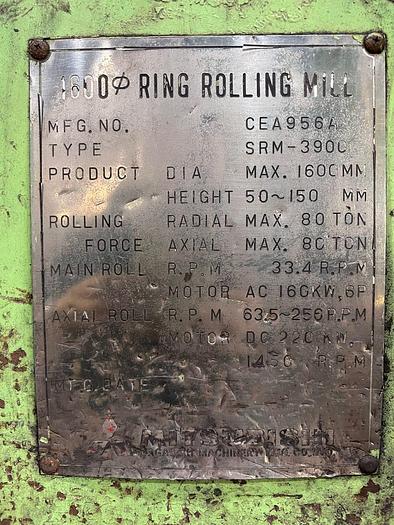

Ring Rolling Line MRS-1600

Specifications

| Manufacturer | Mitsubishi |

| Model | MRS-1600 |

| Year | 1991 |

| Condition | Used |

| Stock Number | MA1633 |

| Item condition | Good working condition |

Description

Automatic Ring Rolling Mill / Mitsubishi Ø 1600 Ring Rolling Mill - Whole Plant consist of

1) Mitsubishi MRX-1600 Ring Rolling Mill - 1 set

-The horizontal / vertical ring rolling mill is provided for rolling seamless rings at forging temperature.

Make : Mitsubishi, Japan

Model : MRS-1600

Yom : 1991

Working Range :

Max out diameter : 1700 mm,

Min Out Diameter : 310 mm,

Max Thickness : 250 mm,

Height of finished Ring : 50 ~ 210 mm,

Height of Ring Blank : max. 250 mm,

Inner Diameter of Ring Blank : min 100 mm,

Outer Diameter of Ring Blank : min 250 mm,

Main Characteristics :

Horizontal Stand -

Rolling force : max. 80 tons

Vertical Stand -

Rolling force : max. 80 tons,

max weight of the rings produced : 400 kg,

2) Hyundai 1500 ton Forging Press - 1 set

Make : Hyundai, Korea

Model : 1500-1500*1200

Yom : 1992,

Capacity : 1500 tons

Stroke : 1100 mm

Daylight : 2110 mm

Slide Space ( FB x LR ) : 1500 x 1200 mm,

Bolster Space (FB x LR ) : 2300 x 1200 mm,

Working Speed, Down : 250 mm/SEL

Working Speed, Pressing : 1500 ton-39 mm/SEL,

Working Speed, Down : 1000 ton - 55 mm/SEL,

Lifting Capacity : 250 mm/SEL , 200 tons,

Moving Bolster :

Caring Capacity : 15 tons,

Movable Stroke : 2100 mm (1100mm)

Dia of Cylinder : 140 mm,

Punch Change Device :

Movable Stroke : 1600 mm (800 mm)

Dia of Cylinder : 80 mm

Knock-Out Device :

Capacity : 10 tons,

Movable Stroke / Dia of Cylinder : 80 mm,

PUMP :

Main Pump Model : A7V500LV5

Pressure : Max 350kg/cm2

Oil Volume : 2200 L/min

Sub Pump Model : A10 VSO 100 DRF

Pressure : 210kg/cm2

Oil Volume : 110 L/min

Cooling Pump Model : NLG 25

Pressure : 6kg/cm2

Oil Volume : 25M3/hr

Motor :

Main Motor

Output : 175Kw 6P * 4 sets

Power : AC300 *60Hz

Sub Motor

Output : 37Kw 4P

Power : AC220V *60Hz

Cooling Motor

Output : 7.5Kw 6P

Power : AC220V *60Hz

Oil tank capacity :

Main Tank : 7000L

Sub Tank : 2500L.

total power requirement of the Ring Mill and Hydraulic Press :

Press : 1200 KW (3300V), Ring Mill : 500 KW (220V)

Heating Furnace :

Heating by Bunker C-Oil, Temperture, Max 1250°C,

Q’ty : Dia 500 x 500L (Round Bar) x 12ea/one time.

Include:

- Rolling Mill

- Manipulator

- Unloader

- Transfer Car

- Mandrel Adjustment Device

- Centering Roll Adaptor