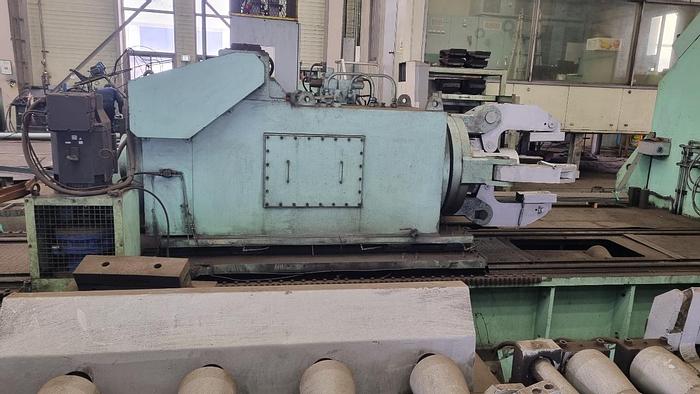

Radial Forging Machine BF350 Neagari Shibuya,Japan

Specifications

| Manufacturer | Neagari Shibuya,Japan |

| Model | BF350 |

| Year | 2010 |

| Condition | New |

| Stock Number | MA1846 |

| Item condition | Good working condition, Periodically Idle running |

| Capacity tons | 0 |

Description

Hydraulic 4 Die Radial Forge

Material

(1) Tool Steel (EX. DIN-X40CrMoV51AISI-H13JIS-SKD)

(2) C-steel

Starting Dimension

(1) Round Max. Diameter φ450 mm

(2) Square Max. Flat to Flat 240 mm

(3) Max. Length 3500 mm

(4) Max. Weight 3000 kgf

Forged Dimension

(1) Min. Diameter φ80 mm

(2) Min. Square 120 mm

(3) Max. Length 8000 mm

(4) Max. Weight 3000 kgf

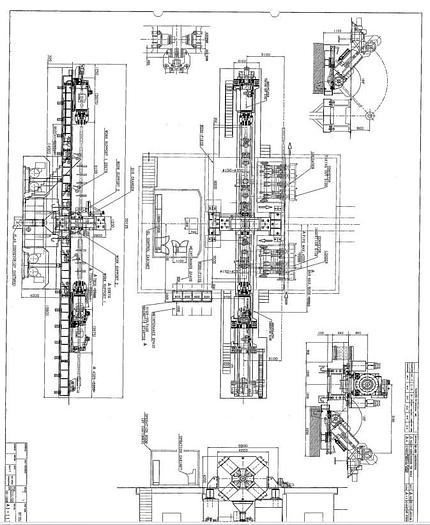

Bar Forging Machine :

Forging Ability

(1) Number of rams 4

(2) Force / ram max. 7000 kN

(3) Hydraulic pressure max. 32 MPa

(4) Opening width 430 - 810 mm (except Die)

(5) All Stroke Length : 190 mm (adjustment unit 1 mm)

(6) High Speed Forging

Mode / Stroke Length / Speed / Forging Force

Planishing / 15 mm / max.120 spm / max. 700 kN

Cogging / 25 - 50 mm / max. 60 spm / max. 7000 kN

(7) Stroke (Bottom Dead Point) Precision ± 0.5 mm

Drive Type

(1) Power Hydraulic

(2) Control Servo-Logic Valve

Control

(1) Two sets of opposing rams work at the same time or in turn.

(2) Manual Control, Auto Control

Dimension

(1) Work Center Height F.L. 800 mm

(2) Width approx. 5400 mm

(3) Height F.L. approx. 3000 mm

(4) Length approx. 2000 mm

(5) Weight approx. 100 tons

Manipulator :

Specifications

(1) Work Weight 3 tons (φ450 x 2400 Iron)

(2) Work Size IN: φ150 - 450 mm x Max.3500L(Material) OUT: φ150( - 450) x Max.8000L

(3) Max. Moment 6 tons・m

(4) Moving Part

-Work Grip Hydraulic servo system

-Work Rotation (Both directions) Servo Motor

-Work Loading (forward-backward) Servo Motor, Rack Pinion

(5) Rotation Speed 0 - 15 rpm

(6) Loading Speed 0 - 30 m/min

Dimension

(1) Work Center Height F.L. 800 mm

(2) Width approx. 2500 mm

(3) Height F.L. approx. 2000 mm

(4) Length approx. 4200 mm

(5) Weight approx. 10 tons

Control Range

(1) Work Rotation -

Continuous Rotation both directions, speed 0 - 15 rpm ·Rotation Pitch min. 15°±1°(0 - 2 rpm)

(2) Work Loading -

Forging Speed below 30 spm → Continuous or Pitch(max.125 mm)

Forging Speed over 30 spm → only Continuous.

Hydraulic System

Specifications

(1) Hydraulic Method for Machine Servo-Logic Valve (with accumulator)

(2) Pressure Max. 32 MPa

(3) Main Pump (for Machine ) 560 L/min (KPM LZ500 series Pump) 8 sets

(4) Motor for Main Pump 600 kW-6P 4 sets

(5) Power Source AC 3300V/380V, 3-Phase, 60Hz

(6) Utility

-Cooling water: Less than 30oC、More than 4000 L/min

-Compressed Air: 0.4 - 0.8 MPa,More than 120 N・m3

Electric Power & Control System

Electricity

(1) Primary Power (by Customer)

-AC 3300V, 3-Phase, 60Hz : 900 kVA x 4 Lines

-AC 380V, 3-Phase, 60Hz : 300 kVA x 1 Line, 350 kVA x 1 Line

(2) Control Voltage - DC 24V

Operation Mode

(1) Manual & Inching - Independent action of each actuator is available

(2) Auto Auto operation from work input to extraction

(3) Step by step Stop after every step

Mandrel Unit (IN)

(1) Mandrel Dia. φ100 -φ175 mm Attachment changing system

(2) Function Rotation: Free Forward & Reverse: All Stroke 5800 mm, Mandrel Cooling: Water Circulation.

Mandrel Unit (OUT)

(1) Thorn Dia. φ100 - φ175 mm Attachment changing system

(2) Function Rotation: Free Forward & Reverse: All Stroke: 600 mm Thorn Cooling: Water Circulation.

Machine components

(1) Bar-Forging Machine : 1 set

(2) Manipulator : 2 sets

(3) Hydraulic System : 1 set

(4) Electric Power & Control System : 1 set

(5) Foundation : 1 set

(6) Unloader : 1 set

(7) Work Support 6 sets

(8) Work Support (center) : 2 sets

(9) Mandrel (IN) : 1 set

(10) Mandrel (OUT) : 1 set

(12) Die Changing Unit : 1 set

All technical documents and manuals available,

Forged Round Bar, Work Roller Parts were being produced on this machine.