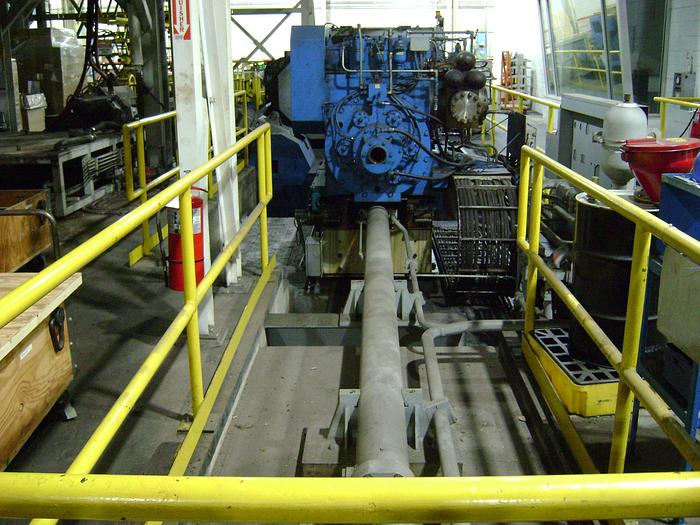

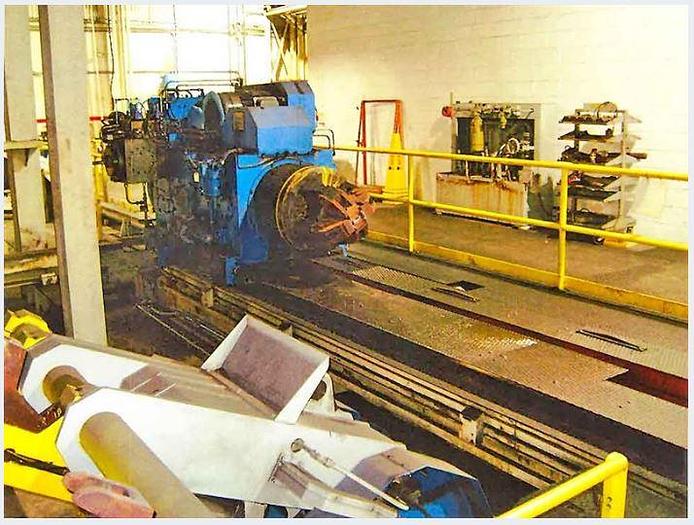

Radial Forging Line GFM SHP-16 (SX-16)

Specifications

| Manufacturer | GFM |

| Model | SHP-16 (SX-16) |

| Year | 1983 |

| Condition | Used |

| Stock Number | MA2089 |

| Item condition | Good condition, dismantled |

Description

800 ton GFM SHP-16 (SX-16) CNC controlled

160 mm dia 4-Die Radial Forge Line

Dia : 160 mm,

Dies/Rolls : Four,

Force of each hammer : 200 tons,

Total forge tonnage : 800 tons,

Hammer length : 326 mm,

Max forging bar diameter : 160 mm,

Max squares with rounded corners : 140 mm,

Min squares with rounded corners : 40 mm,

Max width of forged rectangles : 120 mm,

Max height of forged rectangles : 20 mm,

Max approx. side ratio of forged rectangles : 1:6,

Feed of Manipulator : A5 meters,

Feed of Manipulator : B5 meters,

Total installed power : 450 kW,

Forging height above floor : 750 mm,

Total height above floor : 2,100 mm,

Total length of line : 27 meters,

Max width of line at floor level without loading device :14 meters,

Machine weight : 117 tons.

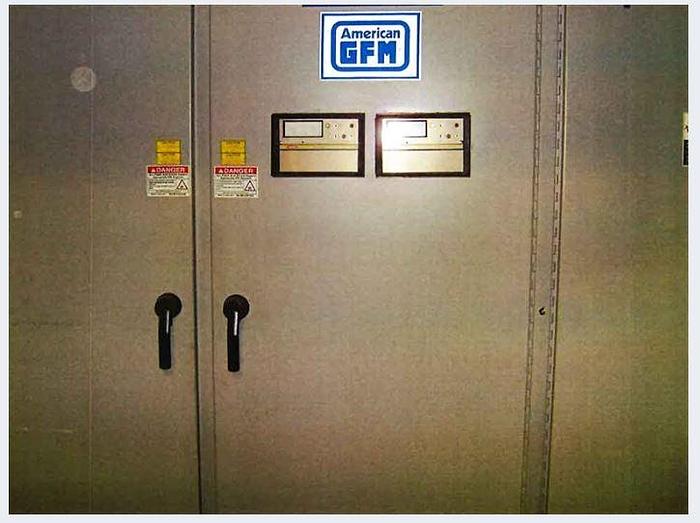

New in 1983, this Radial Forge received a complete Controls upgrade in 2006 with the addition of CNC Controls and a complete mechanical rebuild in 2011, both performed by American GFM

Additional information:

Electrical Power and Ratings:

Main forging motor.......................................... 223.7 kW........................... 300.0 hp

Pump motors ....................................................140.6 kW............................188.5 hp

Chuck head motors.....................................(2) x 30.0 kW......................(2) x 40.0 hp

Electrical power rating.................................... 450.0 kW........................... 603.4 hp

Operating voltage............................................................. 450 volts / 60 Hz

Control voltage................................................................... 115 volts / 60 Hz / 24 V DC

Complete with:

• Mechanical Group consisting of the following:

(1) Forging box with four (4) Forging Hammers

(2) Manipulators

(2) Manipulator beds

(1) Billet Charging system (places billet into work area to be gripped by manipulators)

(1) Discharging system

(1) Inlet roller conveyor system

(1) Outlet roller conveyor system

• GFM Die Changer

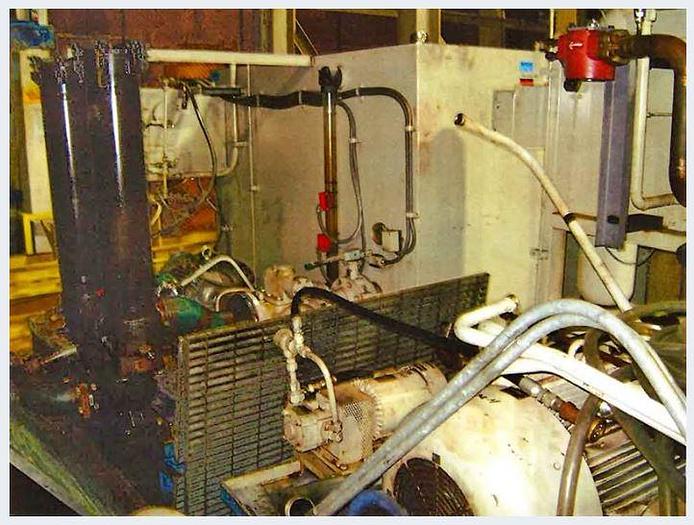

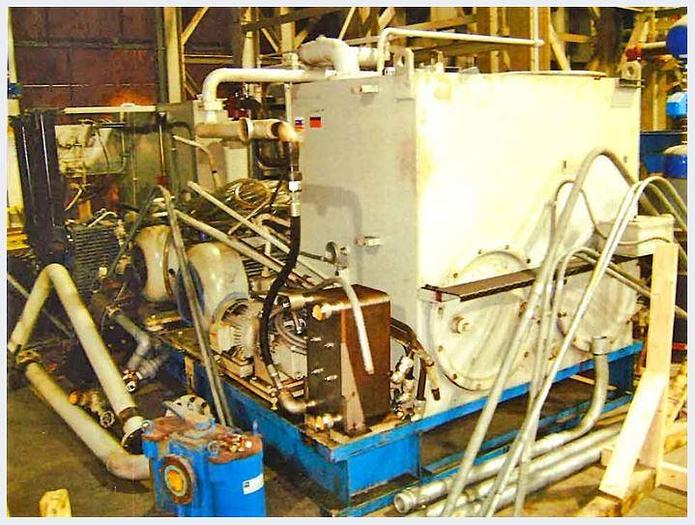

• Complete Hydraulic System

• Complete Lubrication system

• Complete Electrical system including all drive motors and electrical cabinets (450V / 3 / 60Hz)

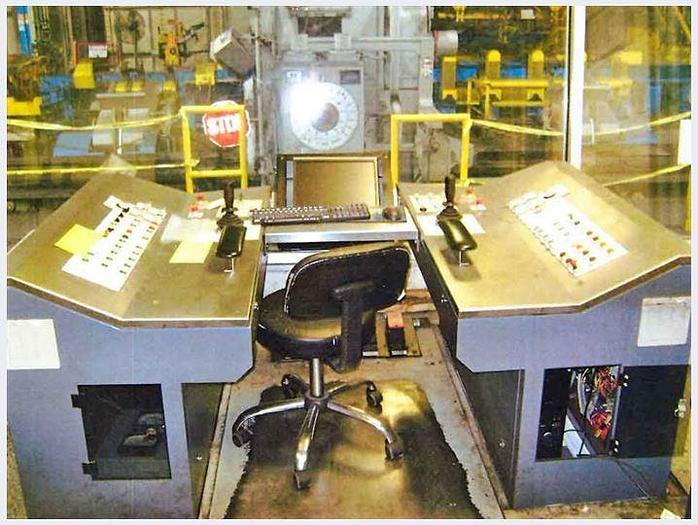

• Complete Electronic CNC Control System designed, upgraded, built & installed in 2006

• Complete Operator’s Control Room with Control Console

• Independent Tool Adjustment feature

• Centering guides

• Block Supports

• Component Change Equipment

• An assortment of Spare Parts

• All available documentation including manuals, drawings, schematics, etc.Wante