Hot Rolling Mill Plate Plant

Specifications

| Year | 1997 |

| Condition | Used |

| Stock Number | MA2373 |

| Item condition | Good working condition |

Description

Manufacturer : DAVY, TMEIC, TOSHIBA, MITSUBISHI, SMS

Type : 4-Hi Rev.

Built : 1997 , Revamped & Installed : 2008, 2011 , Stopped in 7-2017

Revamped cost of USD 151.0 Mill. from 2008 up to 2011

Finishing mill equipped with CVC Roll plus Technology System

Finishing mill – new hydraulic adjustment to increase rolling force to 90 MN

Roughing & Finishing mills: Technology Control System (Level 1)

Process Models (Level 2) for pass schedule calculation, profile & flatness

control (PFC), Pacing system & Material tracking

Revamped by SMS in 2011

Roughing mill : Slipper-type Spindles

Product capacity : 2,000,000 ton/year

Mill capacity : 30 Plates/h

Entry Material : Slab - T130~300mm x W1200~2200 mm x L2350~4000 mm

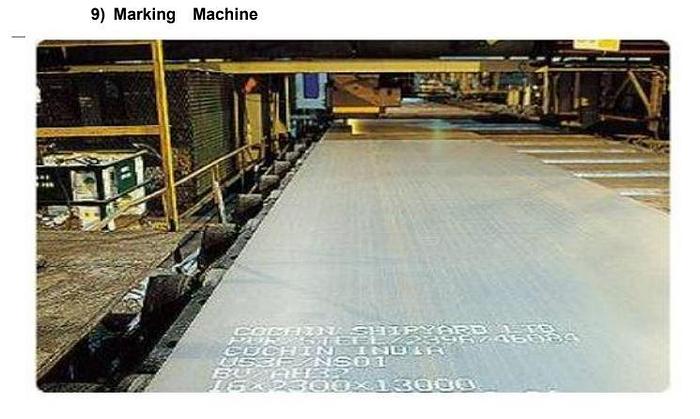

Final Product : Plate - T5~180mm x W1200~4100 mm x L max. 25 meter.

Application : Shipbuilding plate & Pipe production

Power supply : Approx. 120 000 MW

Requested area : approx. 75 000 m2

Scope of supply:

1. Descaler

Mfc. : Davy McKee Built : 1997 Type : Hi-pressure spray Size: 7835 x 5890 mm – L x W

Flow rate : 4550 L/min. Pressure: 228 bar Head no. : 2 ea upper & 2 ea down

Distance between Nozzle and slab : 140 mm

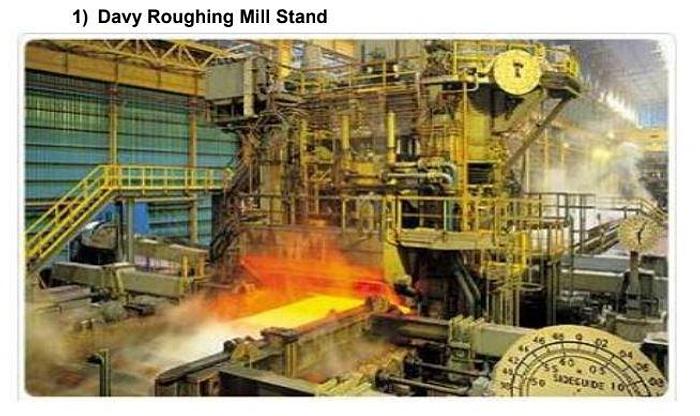

2. Roughing Mill

Mfc.: Davy McKee Type : 4-Hi Reversing Built:1997 Stopped: 2017

Pressing force : max. 9000 T

Qty. 2 Main motors changed to AC 8000 kW each, 45-110 RPM in 2011 Mfc. : TMEIC

Three phase synchronous motor 12 Poles Type : SSCR-CHPCM-DM Rated voltage: 3100 V

Inverter Voltage : 3100 V Frequency : 4.5 – 11.0 Hz

Work roll : Dia. 1120 x 4300 mm L x 8882 mm (TL) Weight: 48 T

Back up roll : Dia. 2150 x 4300 mm L x 9560 mm (TL) Weight : 160 T

3. Finishing Mill

Mfc. : Davy McKee Type : 4-Hi Reversing Built : 1997 Stopped : 2017

Pressing force : max. 9000 T Work roll shifting in 2009 Mfc. : SMS

Qty. 2 New main motor AC 8000 kW each, 45-110 RPM in 2008 Mfc. : TMEIC

Three phase synchronous motor 12 Poles Type: SSCR-CHPCM-DM Rated voltage : 3100 V

Inverter Voltage : 3100 V Frequency : 4.5 – 11.0 Hz

Work roll : Dia. 1,120 x 4,300 mm L x 8970 mm (TL) Weight : 49 T

Back up roll : Dia. 2,150 x 4,300 mm L x 9560 mm (TL) Weight : 160 T

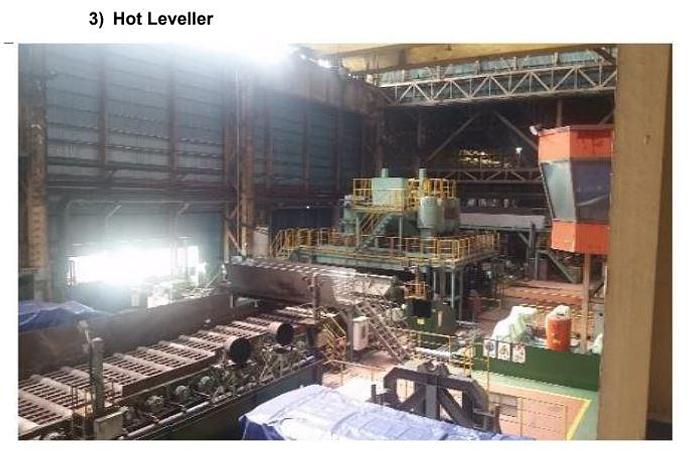

4. Hot Leveller

Mfc.:Taechang Built : 2008 Type : 4-Hi reversing Strip thickness : 5-50 mm Width : 4200 mm

Work roll dia. 280 x 4350 mm L 4 WR Top & 5 WR Bottom Hardness : HS 68+/-3

Hold down roll dia. 400 x 4350 mm L – 2 ea.

Back-up roll dia. 295 x 200 mm L 60 BUR Top & 75 BUR Bottom

Hardness : HS 51-54 Support roll dia. 400 x 4000 mm L - 2 ea.

Levelling Temp. : 450-900 °C Speed: max. 60 m/min.

Capacity : 3000 T at max. size Leveller size: 50 T

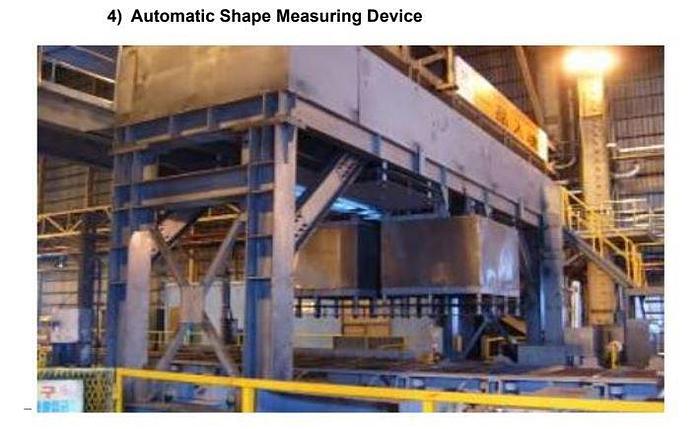

5. Automatic Shape Measuring Device

Mfc.: Marktech Built : 2001 Type : Camera (7 sets) Laser type (2 sets)

Scan angle : 14.24° Scan time : 2 – 4 ms Temp. : 500 – 1100 °C

Thickness : 6 – 300 mm Width : 1200 – 3300 mm Length : 6.0 – 50.0 m

Camber measuring area : max. 300 mm

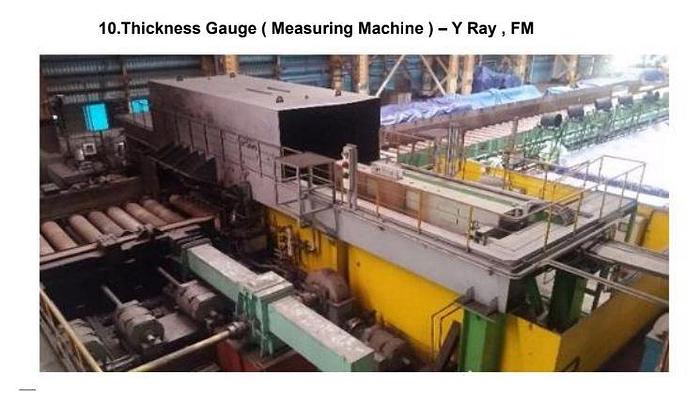

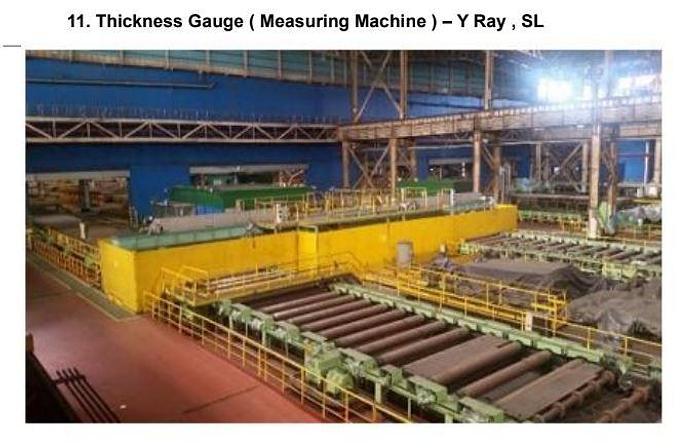

6. Thickness Measuring Machine – Y-RAY

Mfc. : IMS Thickness Radiation: Cesium 137 Measure range : 6-120 mm

Length : 2000 mm over Type : Non contact laser doppler

Width : 1200 mm over Type: Line image camera

7.Roll Shop

Total Weight of the Line : 90,643,342 kgs.

All technical documents and manuals available.

Rolling mill is on Foundation.