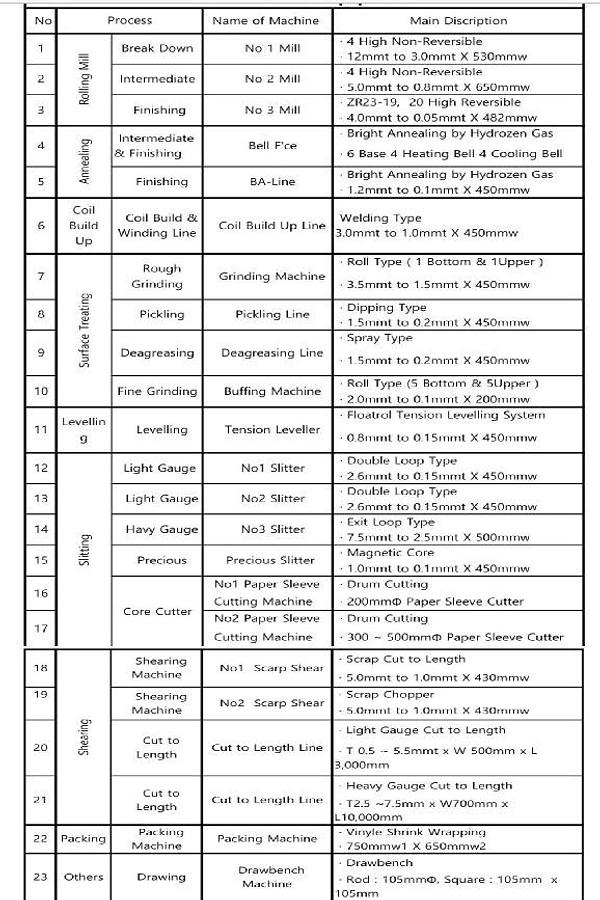

Rolling Mill Copper & Copper Alloys

Specifications

| Manufacturer | Copper & Copper Alloys |

| Condition | Used |

| Stock Number | MA3157 |

| Item condition | Good condition |

Description

Completed Rolling Mill Equipment (Copper & Copper Alloys)

Materials of Products : Copper & Copper Alloys,

Forms of Products : Strip & Sheet,

Range of Products : Thickness 0.05 - 4.5 mm x Width 10 - 450 mm,

Annual Capacity : 6000 tons.

1, Rolling Mill No. 1

318 x 610 x 635 4High Irreversible

· Manufacture

-. Year : 1965. 06

-. Company : Sir James Famer Norton (UK)

· Type : 4 High Irreversible, Work Roll Drive

· Screwdown : Electro Machanical

-. Motor : AC 11Kw 6Pole with Disk Break

-. Reduction Rate : 1650 : 1

· Pass Direction : Left to Right

· Revamping

-. Year : 2017. 09

-. Company : Shinkwang Tech (Korea)

-. Details of Revamping : Input System, Uncoiler, Up-coiler, Electric Drive System

· Thickness Gauge : Non

· Working Data

-. Material : Copper & Copper Alloys

-. Starting Gauge : Max 12 mm

-. Finishing Gauge : Min 3.0 mm

-. Width : 200 - 530 mm

· Coil Data

-. Coil Weight : 1250 Kg

-. Coil Dia : 600 - 850 mmΦ

· Drive Data

-. Un-Coiler : Side Cone Coiler

-. Mill Motor : DC 560Kw 550/1200RPM

-. Up-Coiler : 30Kw VS

·. Line Speed : 75 m/min

· Roll Data

-. Work Roll : Type : 310 mmΦ x 635 mm Barrel Face 8 Pieces

-. Back Up Roll : Type : 610 mmΦ x 635 mm Barrel Face 9 Pieces

· Post Size : 330 x 450 mm

· Coolant System

-. Type : Soluble Oil

-. Filtering System : Catridge

-. Spray : 250 l/mim

· Composition

a. Cone Type Uncoiler.

b. Input Guiding System.

C. Mill

d. Output Guiding System

e. Up-Coiler

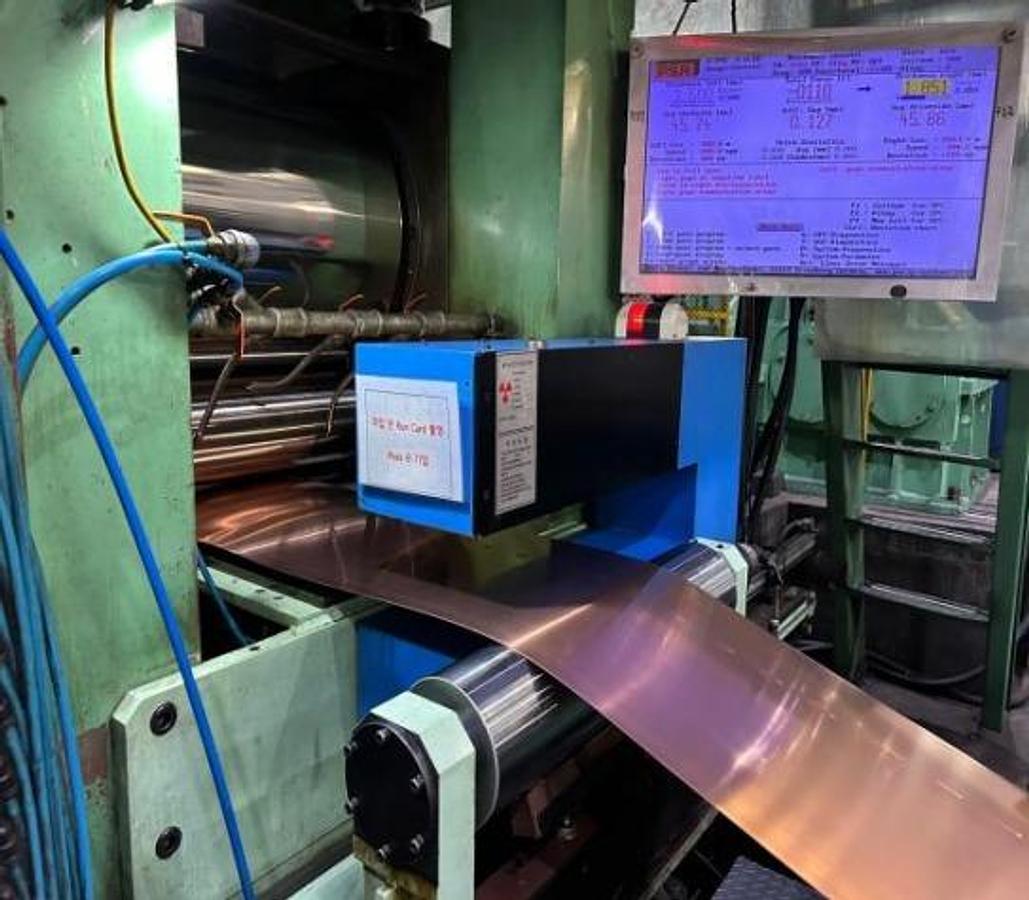

2, Rolling Mill No. 2

225 x 570 x 720 4 High Irrversible

· Manufacture

-. Year : 2017. 06

-. Company : Shinkwang Tech (Korea)

· Type : 4 High Irreversible, Work Roll Drive

· Screwdown : Hydraulic

-. AGC : Pauly System (Germany)

· Pass Direction : Left to Right

· Revamping

-. Year : 2020

-. Company : Partec (Korea)

-. Details of Revamping : Drive System, Hydraulic Screwdown, AGC

· Thickness Gauge : γ-Ray

· Working Data

-. Material : Copper & Copper Alloys

-. Starting Gauge : Max 5mm

-. Finishing Gauge : Min 0.8mm

-. Width : 200 - 650 mm

· Coil Data

-. Coil Weight : 2500 Kg

-. Coil Dia : 508 - 1100 mmΦ

· Drive Data

-. Mill Motor : DC 350 Kw 600/1500RPM Reduction Ratio : 13.1 : 1

-. Unwinder Motor : DC 75Kw 500/1500 Reduction Ratio : 25.5 : 1

-. Rewinder Motor : DC 150Kw 500/1500 Reduction Ratio : 25.5 : 1

-. Line Speed : 90 m/min

· Roll Data

-. Work Roll : Type : 225 mmΦ x 720 mm Barrel Face 14 Pieces

-. Back Up Roll : Type : 570 mmΦ x 670 mm Barrel Face 14 Pieces

· Post Size : 320 x 290 mm

· Coolant System

-. Type : Mineral

-. Filtering System : Catridge

-. Spray : 250 l/mim

· Composition

a. Left Tension Uncoiler

b. Input Guiding System.

C. Mill

d. Output Guiding System

e. Right Tension Recoiler

3, Rolling Mill No. 3

ZR 23-19 20High Mill

· Manufacture

-. Year : 1960

-. Company : Waterburry Farrel (USA)

· Type : 20 High Reversible

· Model Number : ZR 23 - 19

· Screwdown : Hydraulic

-. AGC : Pauly System (Germany)

· Pass Direction : Left to Right

· Revamping

-. Year : 2017

-. Company : Partec (Korea)

-. Details of Revamping : Drive System, AGC

· Thickness Gauge : γ-Ray

· Working Data

-. Material : Copper & Copper Alloys

-. Starting Gauge : Maximum 4mm

-. Finishing Gauge : Maximum 0.05mm

-. Width : 200 - 482mm

· Coil Data

-. Coil Weight : 3000 Kg

-. Coil Dia : 508 - 1200 mmΦ

· Drive Data

-. Mill Motor : DC 225 Kw 600/1000RPM Reduction Ratio : 3.13 : 1

-. Reel Motor : DC 150Kw 300/1200 Reduction Ratio : 12 : 1

-. Line Speed : 120 m/min

· Roll Data

-. Work Roll : 40 mmΦ x 533 mm Barrel Face 364 Pieces

-. Taper Roll : 71 mmΦ x 597 mm Barrel Face 12 Pieces

-. Idle Roll : 128 mmΦ x 533 mm Barrel Face 39 Pieces

-. Drive Roll : 128 mmΦ x 550 mm Barrel Face 33 Pieces

-. Back Up Bearing : 225 mmΦ x 120 mm Face 79 Pieces (3.3 Sets)

· Housing : Mono Block

· Coolant System -. Type : Mineral

-. Filtering System : Supamic

-. Spray : 600 l/mim

· Composition

a. Left Tension Reel

b. Input Guiding System.

C. Mill

d. Output Guiding System

e. Right Tension Reel