Ring Rolling Line Banning RAI40/32

Specifications

| Manufacturer | Banning |

| Model | RAI40/32 |

| Year | 1983 |

| Condition | Used |

| Stock Number | MA3175 |

| Item condition | Good working condition |

| Capacity tons | 1000 |

Description

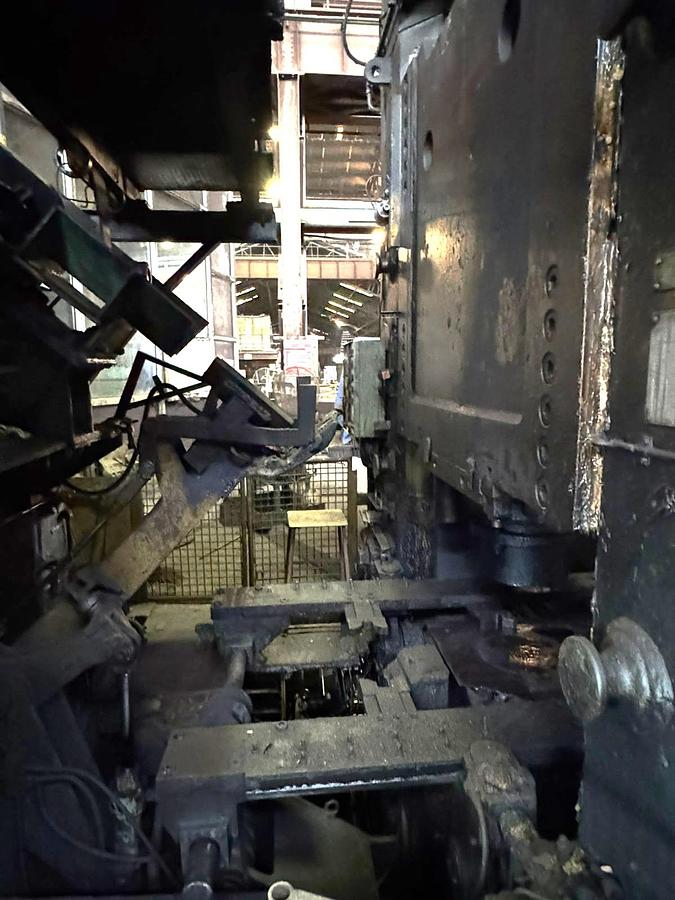

Banning Ring Rolling Mill

1) Ring Rolling Radial Axial Machine

Make : Banning, Germany

Model : RAI 40 / 32

Ring Dia : 130 – 1000 mm

Ring Height : 30 – 210 mm

Outside diameter of ring blank : 120 - 360 mm

Inside diameter of ring blank for mandrel : ø 85 mm - 95 mm,

Ratio of wall thickness to height - max. 4 : 1,

Ring weight - max. 100 kgs

Rolling force infinity adjustable till max : 400 KN

Outside diameter of main roll sleeve : 500 – 650 mm,

Inside diameter of main roll sleeve -: 360 mm,

Height of main roll sleeve : 210 - 230 mm,

Number of revolutions of main roll -approx. 48 rpm,

Rolling speed at main roll dia : 600 mm approx.1.5 m/s,

Normal diameter of mandrel for max. Rolling force,

And maximum mandrel length : 85 mm,

Horizontal stroke of mandrel : 150 mm,

Distance between centre ø of main roll & centre ø of mandrel : 340 mm,

VERTICAL STAND

Rolling force, infinitely adjustable till max. 320 KN

Length of taper rolls, theoretical - 450 mm,

Length of taper rolls usable - 390 mm,

Taper cone angle -45 º,

Horizontal stroke of vertical stand - 1100 mm,

Vertical stroke of upper taper roll - 200 mm,

Max. distance between the taper rolls - 220 mm,

CENTERING ROLL

Centering slides are mountd at the vertical stand.

Center line of the ring to be rolled is in the middle between the Center lines of the centering rollers

Nominal diameter of the centering roll - 170 mm,

Longitudinal stroke of centering slides - 600 mm,

TRACER ROLLER

Force of tracer roller against the ring at set working

Working pressure of 15 bar, approx. 450 n

CARROUSEL

Length of the rolling mandrel - 510 - 590 mm,

Vertical stroke of carrousel - max. 410 mm,

Turning moment of hydro-motor for carrousel rotation,

At working pressure of 160 bar, 16000 nm,

MAXIMUM WORKING SPEED & WORKING TIMES HORIZONTAL STAND

Fast advance in direction to main roll -approx.100 mm/s,

Advance speed during automatic rolling process approx. 0 – 10 mm/s,

Return speed - approx. 100 mm/s

VERTICAL STAND WITH CENTERING ROLLERS

Fast advance in direction to main roll - approx. 350 mm/s,

Advance (+) & return (-) speed during automatic,

Rolling process - approx. 20 – 55 mm/s,

Fast return speed - approx. 350 mm/s,

SLIDE OF UPPER TAPER ROLL

Fast motion downward - approx. 30 mm/s,

Downward motion during automatic,

Rolling process - approx.10 mm/s,

Fast motion upward - approx.20 mm/s

MAXIMUM WORKING PRESSURE HYDRAULIC

General working pressure - 165 bar,

Officially admissible pressure - 210 bar,

Horizontal rolling - 180 bar,

Vertical stand, horizontal motion - 165 bar,

Tracer roller (pressure reducing valve) - 15 bar

PNEUMATIC

Maximum allowable working pressure - 10 bar,

General working pressure - 6 bar,

DRIVING UNIT OF MAIN ROLL DRIVING MOTOR

Normal power - 110 kw,

Voltage - 415 v Current - 185 a,

Nominal speed - 1500 rpm,

MAIN DRIVING GEAR WITH COUPLING

Nominal power - 110 kw,

Nominal speed - 1500 rpm,

Gear ratio - 31.5,

Output speed at input 1500 rpm - 47.5 rpm,

DRIVING UNIT OF UPPER TAPER ROLL DRIVING MOTOR

Nominal power - 110 kw,

Armature voltage - 460 v,

Armature current - 263 a,

Speed at armature regulation, constant moment - 1500 – 2000 rpm,

DRIVING UNIT OF COOLING SYSTEM OF HYDRAULIC POWER UNIT -DRIVING MOTOR

Normal power - 4 kw,

Nominal speed - 1450 rpm,

Voltage - 415 v,

Banning weighing scale

Model no : USC-PD-505,

Class : 3 Min wt:100 gms,

Max wt : 50 kg,

Manufactured : United scales co ltd.

2) Screw Compressor 3

Make : Ingersoll Rand

Sr. No : 20713004

Model No : ML 160

Capacity : 28 Cu M/Min

Type of compressor : Screw compressor

Nominal Operating Pressure : 7.5 BAR

Motor Capacity - 160 kw

3) Niton Spectro Gun

Model - XL2 800, Sr. No : 92968

Make - Thermo Scientific

4) Hand Pyrometer

Model - RAYR312ML3U

Make : Raytek

Sr.No : 23630001

5) Dual Wavelength Online IR Pyrometer for Ring - Qty 4 No

Metal bins non tiltable (Small) : Qty 50 Nos

6) Heater Transformer

TRF SERIAL NO.: 07CNF039

Make : KIRLOSAKAR ELECTRIC CO. LTD.

YEAR OF MFG. : 2007

Capacity - 1600 KVA, Load-1000KW

VOLT AT NO LOAD : HV: REF TABLE;LV: 595V

AMPERES:HV: REF TABLE; LV: 1557.8A

7) Heater Coil with control panels

Dia -90,1000KW-5 Coils and its panels Qty 5 Nos

Dia -110,1000KW-8 Coils and its panels Qty 8 Nos

Dia -135,1000KW-5 Coils and its panels Qty 5 Nos

8) Three Station Ring Blanking Hydraulic Forging Press

Model - OVA1600

Make - Banning, Germany

Year of manufacturing -1983,

Capacity : 1600 tons

Pressing Ram : 650 mm

Ejector : 500 mm,

Stripper cylinder in rem at piercing station : 100 mm,

Transport stroke of walking beam conveyor : 600 mm,

Clamping stroke of walking beam conveyor at each side : 260 mm,

Die clamping table -1600 mm,

Die clamping cylinder - 30 mm,

Die centering cylinder - 25 mm,

FORCES AND SPEED- PRESSING RAM

Max. pressing force at full pressure & small speed - 16000 kn,

Fast down speed (idling) approx. - 350 mm/s,

Fast pressing speed approx. v max. - 46 mm/s,

Medium pressing speed approx. v medium -23 mm/s,

Slow pressing speed approx. v min.- 12 mm/s, Return speed - 350 mm/s,

EJECTOR

Maximum ejector force - 1000 kn,

Ejecting speed adjustable up to max. approx.-190 mm/s,

Return speed- 200 mm/s,

DIE CLAMPING TABLE

Transport speed approx. - 26 mm/s,

MAIN DIMENSIONS

Daylight between table and ram - 1380 mm,

Total width of table and ram (left to right) - 1550 mm,

Clamping width of table and ram (left to right) - 750 mm,

Clamping length of table and ram (front to back) - 1850 mm,

Height of table above floor - 10 mm,

Width of frame windows - 600 mm,

Height of frame windows - 1200 mm,

Depth of press below floor, without ejector - 1440 mm,

Depth of press below floor including ejector - 2440 mm,

Depth below floor for dismantling of ejector - 3400 mm,

Height of press above floor - 6100 mm,

COOLING WATER

Working pressure (approx.) - 5 bar,

Inlet temperature - 35ºc,

Consumption for hydraulic power unit - 11 m³/h,

Consumption for die cooling - 5 m³/h.