Hot Rolling Mill Plate Sumitomo & Posmec

Specifications

| Manufacturer | Sumitomo & Posmec |

| Year | 1972 |

| Condition | Used |

| Stock Number | MA3183 |

| Item condition | Good condition |

Description

1. General Specification

Year of establishment : 1972,

Facility rationalization : 2002,

Year of shut down 09. 2022,

Equipment manufacturer : Sumitomo & Posmec, Stand-Morgan

Material specification Slab (T x W) : 910 x 1450 ~ 1600 x 3000 mm,

Product capacity Initial design criteria : 360,000 ton/year,

Max. production after facility rationalization : 760,000 ton/year,

Product size (T x W x L) : (6.0 ~ 120) x (1250 ~ 3100) x (2400 ~ 22000) mm,

2. Specification of Equipment

2.1 Reheating Furnace

Capacity : 50 ton/hr,

Type : Push type

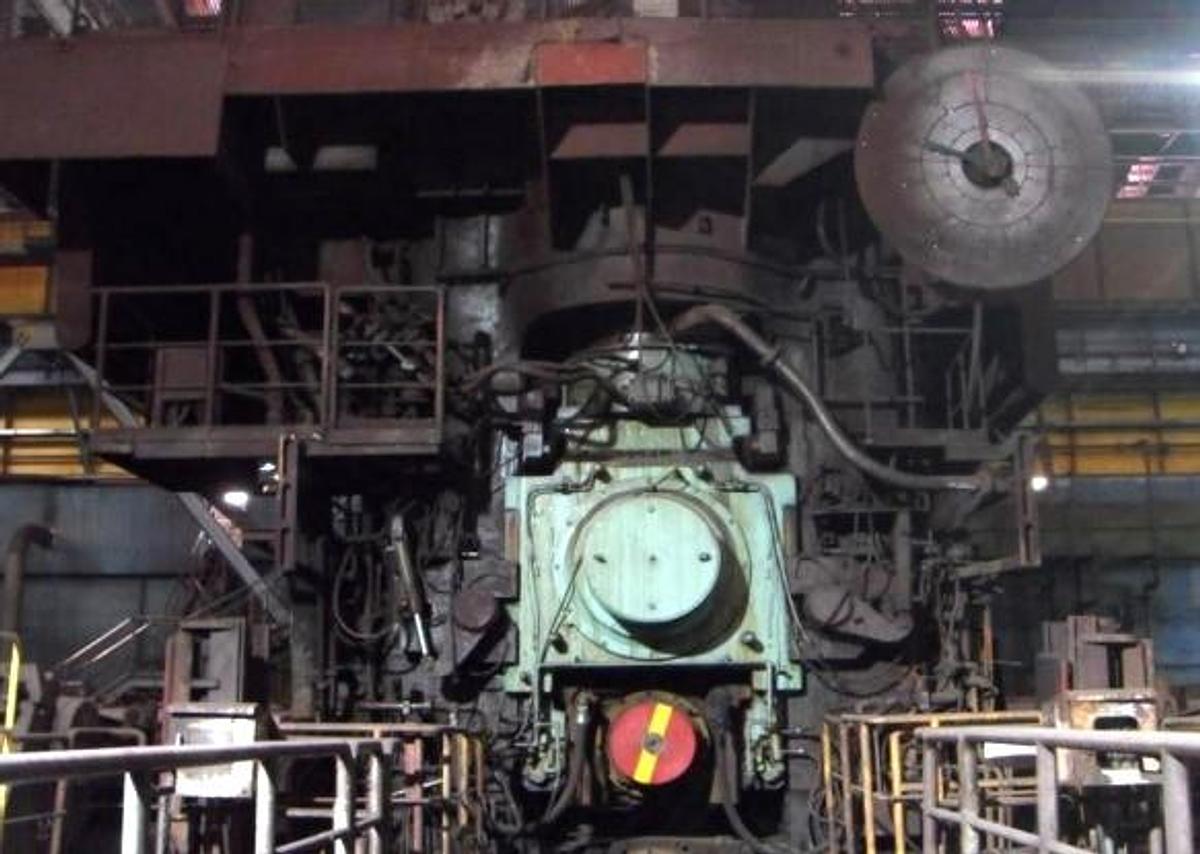

2.2 Finishing Mil

Press capacity : 3600 tons,

Torque max. : 180 Tm,

Type : 4Hi - Reversible,

Mill motor : DC 3,200 KW x 2 sets TMEIC Japan,

Roll size :

Work roll : 840 mm Ø ~ 900 mm Ø x 3350 mmL,

Back up roll : 1460 Ø ~1500 Ø x 3200 mmL,

AGC :

Size : 965 mm Ø x 900 mmL x st 35,

Hydraulic : 280 kg/cm2,

Force : max. : 1800 ton sx 2stes,

Speed : max. : 20 mm/sec.

2.3 Hot leveller

Type : 4Hi - Reversible,

Capacity : 1800 tons,

Motor : 185 KW x 2 sets,

Roll size :

Work roll 230 mm Ø x 3300 mmL,

Back up roll : 235 mm Ø x 225 mmL,

Levelling range : 6 mmT ~ 40 mmT,

Roll quantity :

Up roll : work roll-5ea, back up roll-45ea

Down roll : work roll-6ea, back up roll-54ea

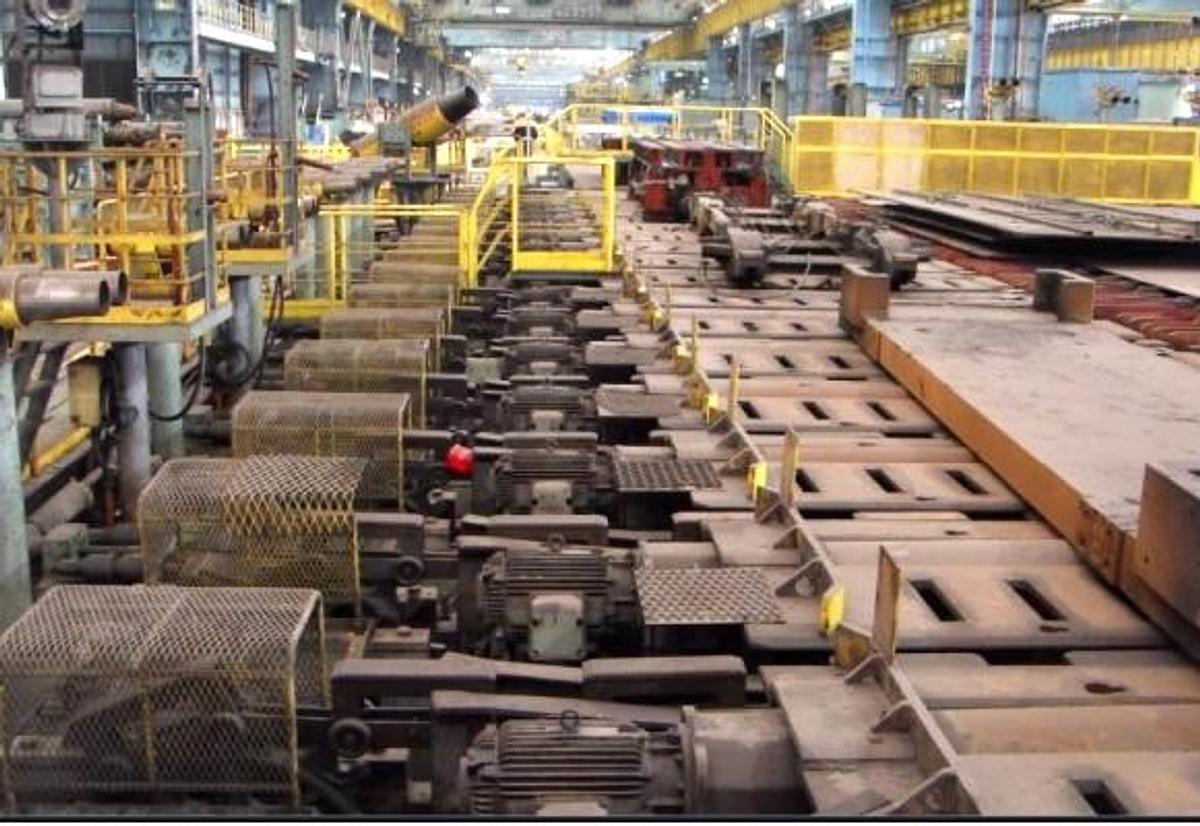

2.4 Coling bed

Size : 32 x 42 m,

2.5 Utility

Water treatment plant

Air com.

2.6 Roll shop : Roll grinder

Bearing remover, Gas cutter, Etc.

3. Composition of equipment

3.1 Reheating furnace Composition

Weight : 2200 tons,

Depiler T/B & Lift, Entry T/B, Pusher, Extractor, Exit R/T, Hyduralic system, Lub. System, Combustion blower & duct, Bunner, Instrument system, Electric panel & desk.

3.2 Mill line composition

Weight : 3800 tons,

Approch T/B, Turn T/B, Entry side guide, Mill stand & motor, Exit side guide, Run out T/B, Hot leveller, R/T, Hydraulic system, Lub. system, Descaling system, Instrument system, Electric panel & desk.

3.3 Cooling bed composition

Weight : 1590 tons,

Cooling bed, Instrument system, Electric panel & desk

3.4 Shear line composition

Weight : 920 tons,

RST Entry R/T, Rotary side trimmer, RST Exit R/T, Dividing shear, DS Exit shear R/T, SHL hyd. system, SHL Lub. System.

3.5 Finishing line composition :

Weight : 280 tons,

IM Entry R/T, Inspection & marking machine, IM Exit R/T, IM Hyd. System, IM Lub. System, Annealed furnace entry R/T, Annealed furnace exit R/T, Instrument system, Electric panel & desk.

3.6 Utility line composition

Weight : 2190 tons,

Water treatment plant, Air compressure plant, Piping , Instrument system, Electric panel & desk.

3.7 Roll shop composition

Weight : 260 tons

3.8 Etc. equipment

Weight : 560 tons

Total weight : 11,800 tons

The weight of the equipment may differ from the actual weight, so please only check the garage.

Technical manuals available.